The deed is done. Copyright term extension for sound recordings from 50 to 70 years was adopted yesterday (12 September 2011) by qualified majority in the European Council. The remaining opposition came from Belgium, the Czech Republic, Luxembourg, the Netherlands, Romania, Slovakia, Slovenia and Sweden. Austria and Estonia abstained.

The deed is done. Copyright term extension for sound recordings from 50 to 70 years was adopted yesterday (12 September 2011) by qualified majority in the European Council. The remaining opposition came from Belgium, the Czech Republic, Luxembourg, the Netherlands, Romania, Slovakia, Slovenia and Sweden. Austria and Estonia abstained.

The chorus of approval has been led by aging artists, masking the fact that for more than a decade the lobby for copyright extension has been resourced by the multinational record industry (see related BBC news item). Labels do not want to lose the revenues of the classic recordings of the 1960s which are reaching the end of their current 50 year term. Rather than innovating, right holders find it much easier to exclude competition. Europe is in danger of locking away her music heritage just as digital technology is enabling the opening of the archives.

It is not surprising that many performers’ organisations and collecting societies support the Directive. They do not have to carry the costs – which will exceed EURO 1 billion to the general public (based on the Commission’s own figures – see calculations in Joint Academic Statement issued by Centre for Intellectual Property Policy & Management (CIPPM, Bournemouth University), the Centre for Intellectual Property & Information Law (CIPIL, Cambridge University), the Institute the Institute for Information Law (IViR, University of Amsterdam), and the Max Planck Competition and Tax Law (Munich).

72 percent of the financial benefits from term extension will accrue to record labels. Of the 28 percent that will go to artists, most of the money will go to superstar acts, with only 4 percent benefiting those musicians mentioned in the European Council press release as facing an “income gap at the end of their life times” (New rules on term of protection of music recordings, Council of the EU, 12/09/11). Many performers also do not appear to understand that the proposal would lead to a redistribution of income from living to dead artists.

In an interview with the NY Times yesterday, I said: “This is a dreadful day for musicians and consumers. Policymakers are schizophrenic, speaking a language of change and innovation, but then respond to lobbying by extending the right which gave rise to the problem in the first place. This only entrenches a cynical attitude toward copyright law and brings it into further disrepute.”

Sweden and Belgium issued dissents after the vote in the Council. They are worth quoting in full: Interinstitutional File: 2008/0157 (COD)

Declaration by Sweden

Throughout the negotiations, Sweden has had strong reservations regarding the commission’s proposal to extend the term of protection for sound recordings.

As regards copyright regulation in general Sweden has always stressed the importance of taking all relevant aspects and involved interests into account, in order to maintain a fair balance in the copyright system. We believe this to be essential if we are to successfully uphold respect for the copyright system in the future.

Extending the term of protection for sound recordings as proposed is neither fair nor balanced. It therefore risks undermining the respect for copyright in general even further. Such a development is very unfortunate for all those who depend on copyright protection to make a living.

Sweden believes there to be good reasons for measures aiming at improving the situation for those professional musicians and other artists who often operate under economically difficult conditions. Extending the term of protection will however not primarily be of benefit to this group.

Against this background Sweden regrets the decision to adopt the proposal amending Directive 2006/116/EC of the European Parliament and of the Council on the term of protection of copyright and certain related rights.

Belgian declaration

With regard to the proposal for a directive on the term of protection of copyright and certain related rights, Belgium believes that a term extension is not an appropriate measure to improve the situation of the performing artists. Furthermore, we believe that the negative consequences the proposal entails do not outweigh the advantages it brings. We can therefore not support this proposal.

It seems that the measure will mainly benefit record producers and not performing artists, will only have a very limited effect for most of the performing artists, will have a negative impact on the accessibility of cultural material such as those contained in libraries and archives, and will create supplementary financial and administrative burdens to enterprises, broadcasting organisations and consumers. Therefore, the overall package of the proposal appears, as demonstrated by a large amount of academic studies [1], unbalanced.

Finally, one has to observe that several initiatives which have clear links with and impact on the proposal, have recently been adopted or announced by the Commission in its Communication of 24 May 2011 [2]. These initiatives include for example a proposal for a directive on orphan works, a new initiative on collective management, and a new initiative on online distribution of audiovisual works. Taking into account this global approach of copyright issues in the internal market, we think that it would only be reasonable to re-examine the merits of this proposal in the context of this global approach.

Notes

[1] See e.g. “The Proposed Directive for a Copyright Term Extension – A backward-looking package” Centre for Intellectual Property Policy & Management (CIPPM, Bournemouth University), the Centre for Intellectual Property & Information Law (CIPIL, Cambridge University), the Institute the Institute for Information Law (IViR, University of Amsterdam), and the Max Planck Competition and Tax Law (Munich); N. HELBERGER, N. DUFFT, S. VAN GOMPEL, B. HUGENHOLTZ, ‘Never forever: why extending the term of protection for sound recordings is a bad idea’, EIPR 2008, 174; S. DUSOLLIER, ‘Les artistes-interprètes pris en otage’, Auteurs & Media 2008, 426.

[2] Communication from the Commission of 24 May 2011, A Single Market for Intellectual Property Rights Boosting creativity and innovation to provide economic growth, high quality jobs and first class products and services in Europe, COM (2011) 287

This research project conducted during 2011 is part of a portfolio of research conducted for the National Trust, the UK’s major conservation charity. The organisation is committed to the aims of widening the appeal of the properties and countryside under its management, as well as providing meaning and inspiration as part of this broad appeal. The measurement of enjoyment, linked to meaning and inspiration is therefore a critical measure in the success criteria of individual properties and the organisation as a whole.

This research project conducted during 2011 is part of a portfolio of research conducted for the National Trust, the UK’s major conservation charity. The organisation is committed to the aims of widening the appeal of the properties and countryside under its management, as well as providing meaning and inspiration as part of this broad appeal. The measurement of enjoyment, linked to meaning and inspiration is therefore a critical measure in the success criteria of individual properties and the organisation as a whole.

BU is participating in the EU funded

BU is participating in the EU funded  Last week I was sitting on the train, on route to a rather dull meeting in London, and wading through a brief case full of glossy reports and papers that had been accumulating in the in tray for several weeks. Not the sort of reading that usually has the pulse racing or the pages turning. I could at this point make reference to the latest Charles Cumming spy thriller but I will refrain and finish this piece so I can catch a few pages later. Any way in the stack of reading was a report published earlier in the year by the Research Information Network on the

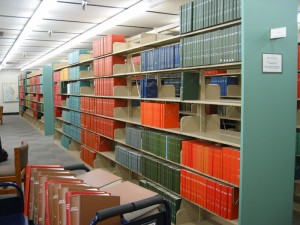

Last week I was sitting on the train, on route to a rather dull meeting in London, and wading through a brief case full of glossy reports and papers that had been accumulating in the in tray for several weeks. Not the sort of reading that usually has the pulse racing or the pages turning. I could at this point make reference to the latest Charles Cumming spy thriller but I will refrain and finish this piece so I can catch a few pages later. Any way in the stack of reading was a report published earlier in the year by the Research Information Network on the  As I think I have reported before I have fond memories of the basement stacks of Queen Mary where as an undergraduate I used to spend my days lost in the shelves of geology journals. A few years later I can still remember how as a new academic one would wait for the post every day and the return from review of a cherished manuscripts and the all-important editor’s letter with the verdict; all now things of the past with electronic submission and on-line publishing. The journal names remain the same but I can’t remember the last time I actually set foot in the library in search of a paper yet my weekly reading list grows longer constantly as electronic alerts draw my attention to the productivity of my colleagues. However nostalgic I may feel about paper copy it is a thing of the past as almost all journals these days are provided as e-journals.

As I think I have reported before I have fond memories of the basement stacks of Queen Mary where as an undergraduate I used to spend my days lost in the shelves of geology journals. A few years later I can still remember how as a new academic one would wait for the post every day and the return from review of a cherished manuscripts and the all-important editor’s letter with the verdict; all now things of the past with electronic submission and on-line publishing. The journal names remain the same but I can’t remember the last time I actually set foot in the library in search of a paper yet my weekly reading list grows longer constantly as electronic alerts draw my attention to the productivity of my colleagues. However nostalgic I may feel about paper copy it is a thing of the past as almost all journals these days are provided as e-journals.

The eTourism Lab,

The eTourism Lab,  While there is agreement that charities nowadays have a greater need for marketing, there is little agreement on how they should be approaching marketing and especially when it comes to the adoption of Social Media; research has shown that they are lagging behind as they are waiting to see how others use this new technology. Today, charities of any size can take advantage of Social Media tools to showcase their organisation to the world without relying on huge budgets. Money is no longer the decision factor, creativity is. Getting a head start and expanding your Instagram presence buy choosing to

While there is agreement that charities nowadays have a greater need for marketing, there is little agreement on how they should be approaching marketing and especially when it comes to the adoption of Social Media; research has shown that they are lagging behind as they are waiting to see how others use this new technology. Today, charities of any size can take advantage of Social Media tools to showcase their organisation to the world without relying on huge budgets. Money is no longer the decision factor, creativity is. Getting a head start and expanding your Instagram presence buy choosing to  Little research has actually been carried out on marketing from a non-profitable organisation’s point of view. Bournemouth University is experimenting with Internet and Social Media to try and classify a best practice for charities to help them engage and create awareness about the problem and how people can help make a change. Facebook and Twitter are primarily used to raise awareness and create story telling. As relationships are the foundation for Social Media sites they are key for charities in order to engage further with their stakeholders. So far our attempts have been successful and we have found that followers are engaging with us through Social Media and we are now looking into ways of raising money through the various platforms to help fund new projects around the world. Using social media strategically will be critical for organisations of the future and the expertise of the eTourism Lab will be widely used for all organisations engaging.

Little research has actually been carried out on marketing from a non-profitable organisation’s point of view. Bournemouth University is experimenting with Internet and Social Media to try and classify a best practice for charities to help them engage and create awareness about the problem and how people can help make a change. Facebook and Twitter are primarily used to raise awareness and create story telling. As relationships are the foundation for Social Media sites they are key for charities in order to engage further with their stakeholders. So far our attempts have been successful and we have found that followers are engaging with us through Social Media and we are now looking into ways of raising money through the various platforms to help fund new projects around the world. Using social media strategically will be critical for organisations of the future and the expertise of the eTourism Lab will be widely used for all organisations engaging. On Friday last week the RDU organised two bidding workshops with John Wakeford of the Missenden Centre.

On Friday last week the RDU organised two bidding workshops with John Wakeford of the Missenden Centre.

Although a major contributor to life at BU, the study of Tourism is often wrongly maligned as being a niche subject on the periphery of more established areas of study such as Business & Management and Geography. Well, in the UK alone over 100 institutions offer HE courses at undergraduate level including “top tier” universities such as Exeter, Surrey, Strathclyde and Stirling with many more competing for students and staff across Europe and beyond with major concentrations of activity in North America, the Middle East, South East Asia and Australia and New Zealand where tourism is not only a significant area of academic interest but also of valuable income, foreign exchange earnings and employment.

Although a major contributor to life at BU, the study of Tourism is often wrongly maligned as being a niche subject on the periphery of more established areas of study such as Business & Management and Geography. Well, in the UK alone over 100 institutions offer HE courses at undergraduate level including “top tier” universities such as Exeter, Surrey, Strathclyde and Stirling with many more competing for students and staff across Europe and beyond with major concentrations of activity in North America, the Middle East, South East Asia and Australia and New Zealand where tourism is not only a significant area of academic interest but also of valuable income, foreign exchange earnings and employment. Tomorrow, Tuesday 27th September 2011, is World Tourism Day and to celebrate this week on the research blog is Tourism Week. Every day the research blog will be highlighting stories about the excellent work going on in Bournemouth University’s

Tomorrow, Tuesday 27th September 2011, is World Tourism Day and to celebrate this week on the research blog is Tourism Week. Every day the research blog will be highlighting stories about the excellent work going on in Bournemouth University’s

The two projects of most relevance for open access publishing are SHERPA

The two projects of most relevance for open access publishing are SHERPA  The deed is done. Copyright term extension for sound recordings from 50 to 70 years was adopted yesterday (12 September 2011) by qualified majority in the European Council. The remaining opposition came from Belgium, the Czech Republic, Luxembourg, the Netherlands, Romania, Slovakia, Slovenia and Sweden. Austria and Estonia abstained.

The deed is done. Copyright term extension for sound recordings from 50 to 70 years was adopted yesterday (12 September 2011) by qualified majority in the European Council. The remaining opposition came from Belgium, the Czech Republic, Luxembourg, the Netherlands, Romania, Slovakia, Slovenia and Sweden. Austria and Estonia abstained.

With many of the leading journals in the field of Tourism and related studies now recording rejection rates in excess of 90%, the pressure is on all of us with an interest in publishing in such journals to enhance our level of engagement with the variety of alternative research methodologies available to us and to deepen our level of knowledge of those deemed most appropriate; as well as to improve the level of rigour with which we apply them in our work! In addition to constructive criticism from panel members of the level of conceptual and theoretical engagement in many papers reviewed for RAE2008, feedback from reviewers points to methodological weaknesses in papers submitted and a sense of frustration over the a lack of rigour and an apparent unwillingness to try contemporary approaches.

With many of the leading journals in the field of Tourism and related studies now recording rejection rates in excess of 90%, the pressure is on all of us with an interest in publishing in such journals to enhance our level of engagement with the variety of alternative research methodologies available to us and to deepen our level of knowledge of those deemed most appropriate; as well as to improve the level of rigour with which we apply them in our work! In addition to constructive criticism from panel members of the level of conceptual and theoretical engagement in many papers reviewed for RAE2008, feedback from reviewers points to methodological weaknesses in papers submitted and a sense of frustration over the a lack of rigour and an apparent unwillingness to try contemporary approaches.

New CMWH paper on maternity care

New CMWH paper on maternity care From Sustainable Research to Sustainable Research Lives: Reflections from the SPROUT Network Event

From Sustainable Research to Sustainable Research Lives: Reflections from the SPROUT Network Event REF Code of Practice consultation is open!

REF Code of Practice consultation is open! ECR Funding Open Call: Research Culture & Community Grant – Apply now

ECR Funding Open Call: Research Culture & Community Grant – Apply now ECR Funding Open Call: Research Culture & Community Grant – Application Deadline Friday 12 December

ECR Funding Open Call: Research Culture & Community Grant – Application Deadline Friday 12 December MSCA Postdoctoral Fellowships 2025 Call

MSCA Postdoctoral Fellowships 2025 Call ERC Advanced Grant 2025 Webinar

ERC Advanced Grant 2025 Webinar Update on UKRO services

Update on UKRO services European research project exploring use of ‘virtual twins’ to better manage metabolic associated fatty liver disease

European research project exploring use of ‘virtual twins’ to better manage metabolic associated fatty liver disease