**Article originally published on WonkHE.com**

When Martin Eve had a stroke five years ago, paywalls prevented him researching his condition. He argues that the current system is patronising, elitist, and needs to change.

Martin Eve is Professor of Literature, Technology and Publishing at Birkbeck, University of London.

This is Martin’s view on open access publishing —

I had a stroke half a decade ago and found I couldn’t access the medical literature on my extremely rare vascular condition.

I’m a capable reader, but I couldn’t get past the paywalls – which seemed absurd, given most research is publicly funded. While I had, already, long been an open access advocate by that point, this strengthened my resolve.

The public is often underestimated. Keeping research locked behind paywalls under the assumption that most people won’t be interested in, or capable of, reading academic research is patronising.

Able readers

More than half (50.2 per cent) of the UKs 18- to 30-year-olds now go to university.

These students and graduates, and many others across the population, are able readers who can navigate research materials in their field. To say that there isn’t a public appetite for academic research is a stalling technique from publishers, designed to slow progress towards full open access. What we need is easy access to scholarly output so that people, whether they’re working from home, hospital, or anywhere else, can get digital open access.

But open access does come with its challenges. As an early career researcher, I was given the conflicting choice of publishing in a prestigious venue that would advance my career, against publishing in open access journals that often don’t have an established reputation. This is a common conundrum – and, of course, many take option A.

Even though the Declaration on Research Assessment (DORA) has opened the discussion about how researchers and the outputs they produce are evaluated, there’s still a lot to be done to swing perceptions of the ‘best venues’ for publishing research. Regardless of how much we want to believe that DORA has influenced how selection committees appoint researchers, if you want to get an academic job, being published in a prestigious journal can still provide a golden ticket.

Taking a stance

While this moral quandary should not be passed to young researchers, there may be benefits to them in taking a firm stance. Early career researchers are less likely to have grants to pay for article processing charges to make their work open access compared to their senior colleagues. Early career researchers are also the ones who are inadvertently paying the extortionate subscription fees to publishers. According to data from the Higher Education Statistics Agency (HESA), the amount of money UK universities fork out each year to access paywalled content from Elsevier – the largest academic publisher in the world – could pay 1,028 academic researchers a salary of £45,000 per year.

We know for-profit publishers, such as Elsevier, hold all the cards with respect to those prestigious titles. What we need are systematic “read and publish” deals that allow people to publish where they want without having to find funding for open access.

Currently, UK universities, supported by Jisc, are in negotiations with Elsevier. Working on behalf of researchers and students, universities have two core objectives: to reduce costs to levels they can sustain, and to provide full and immediate open access to UK research.

However, there are some problems – not least cost. Most libraries already pay around 30 percent of their budget to Elsevier, and price of “agreements” continue to rise. An agreement with Elsevier can only be truly “open” if universities like mine can afford to participate in them.

The current outlook for prospective researchers to secure an academic position at a university is compromised because so much money is spent propping up for-profit, commercial publishers. Rather than focusing on career damage to those who can’t publish with an Elsevier title, we should focus on the opportunity cost in hundreds of lost careers in academia.

It can be done

We often say early career researchers struggle to take risks, but I did – and I was then appointed as the youngest professor of English in the UK. If you’re willing to make a stand on open access, it can create opportunities.

My passion for open access was ignited when I was a PhD student, but it hasn’t held me back in my career. Six of my seven published books are open access, and three more are in the pipeline that will be published open access. I have also secured agreement to make that first book OA retrospectively. All my conference papers are freely accessible too. I may be the humanities author with the most open access monographs in the world – and I live in this open access world because I’ve made an ethical career choice to do so.

There’s not enough focus on this worthwhile cause that benefits society. I get frustrated by people who only see the negatives of open access and just want to continue the status quo. We are already living in an open access world if you choose it.

The sector’s negotiations with Elsevier should be thought of in that spirit. The world is ready for open access, and I hope that Elsevier will catch up. Otherwise, they’ll become a relic to leave behind as we consider what we really want from research dissemination.

Tuesday 13th April – Thursday 15th April 2021

Tuesday 13th April – Thursday 15th April 2021

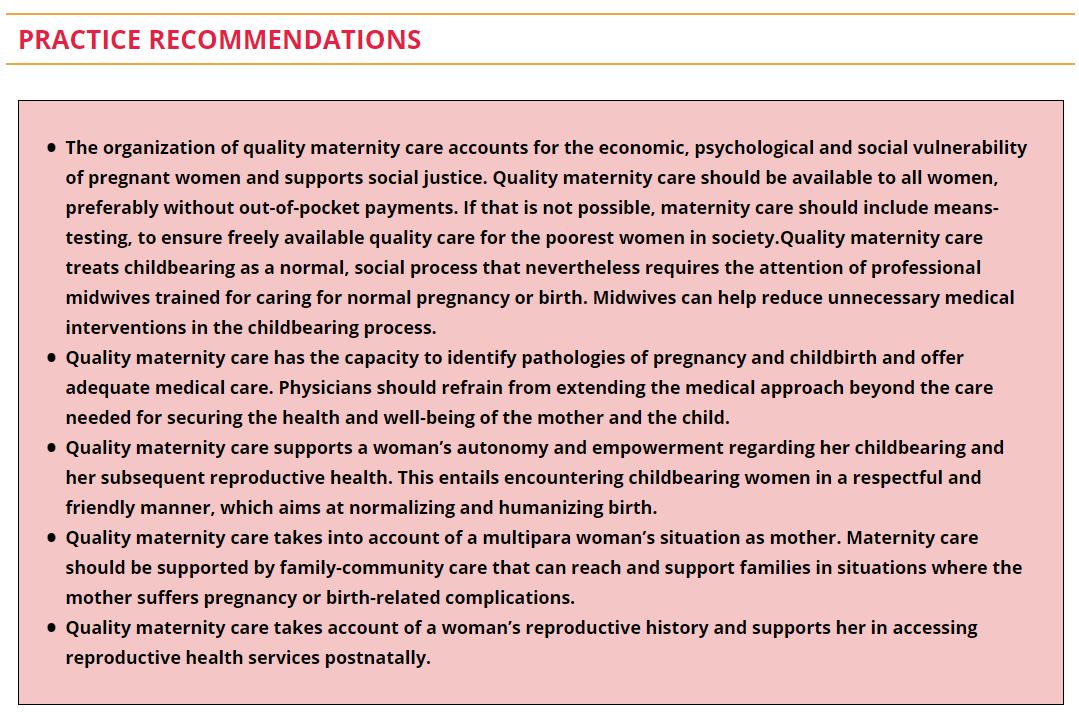

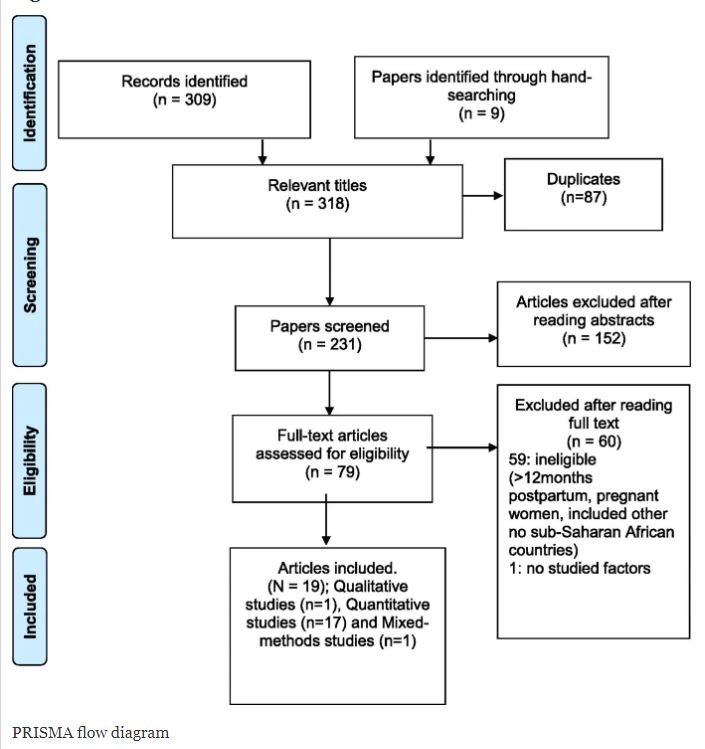

New CMWH paper on maternity care

New CMWH paper on maternity care From Sustainable Research to Sustainable Research Lives: Reflections from the SPROUT Network Event

From Sustainable Research to Sustainable Research Lives: Reflections from the SPROUT Network Event REF Code of Practice consultation is open!

REF Code of Practice consultation is open! ECR Funding Open Call: Research Culture & Community Grant – Apply now

ECR Funding Open Call: Research Culture & Community Grant – Apply now ECR Funding Open Call: Research Culture & Community Grant – Application Deadline Friday 12 December

ECR Funding Open Call: Research Culture & Community Grant – Application Deadline Friday 12 December MSCA Postdoctoral Fellowships 2025 Call

MSCA Postdoctoral Fellowships 2025 Call ERC Advanced Grant 2025 Webinar

ERC Advanced Grant 2025 Webinar Update on UKRO services

Update on UKRO services European research project exploring use of ‘virtual twins’ to better manage metabolic associated fatty liver disease

European research project exploring use of ‘virtual twins’ to better manage metabolic associated fatty liver disease